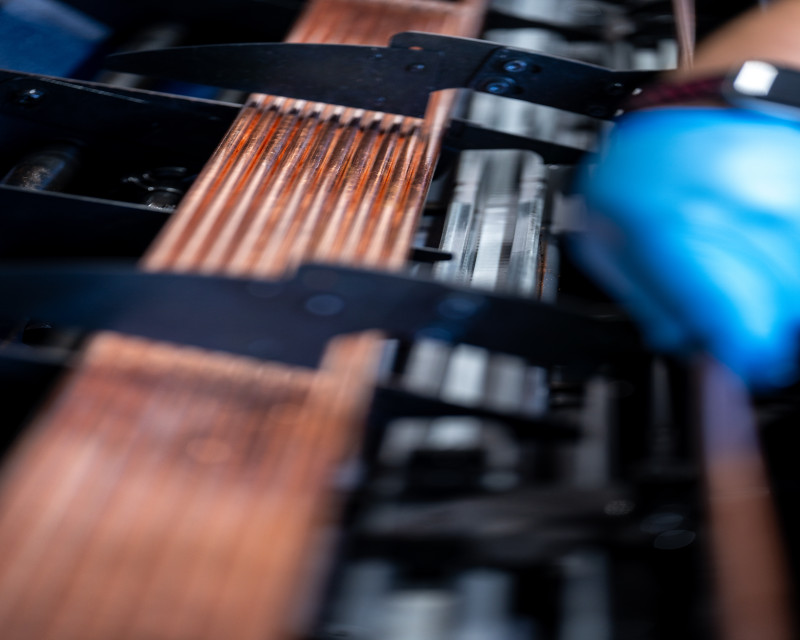

Solid Copper for Penetration, Expansion and Design Flexibility

Premier projectiles are made of solid copper, which not only improves the structural integrity of the projectile, but also facilitates controlled penetration and expansion upon impact. Controlled expansion is critical for optimizing terminal ballistics and increasing stopping power.

Projectile manufacturing involves the creation of bullets or other types of ammunition designed for use in firearms. The precision and quality of these projectiles are crucial for the accuracy, reliability, and overall performance of firearms. The choice of materials used in manufacturing directly influences the projectile's ballistic characteristics, penetration capabilities, and terminal effectiveness.

The Role of Copper in Ammunition Production:

Copper is a popular material for projectile manufacturing, and for good reason. Its unique properties make it an ideal choice for creating effective and reliable ammunition. Here are some key reasons why quality copper is essential in the production of projectiles:

-

Density and Weight Distribution: Copper has a high density, allowing manufacturers to create projectiles with optimal weight for specific calibers. This density contributes to better weight distribution, which is crucial for maintaining stability during flight and ensuring accuracy.

-

Malleability and Formability: Copper's malleability and formability are advantageous in the manufacturing process. These properties allow for precise shaping of bullets, resulting in consistent aerodynamics and enhanced ballistic performance.

-

Jacketing for Penetration and Expansion: Many bullets feature a jacket made of copper, which surrounds a lead core. This jacketing not only improves the structural integrity of the projectile but also facilitates controlled expansion upon impact. Controlled expansion is critical for optimizing terminal ballistics and increasing stopping power.

-

Corrosion Resistance: Copper is known for its corrosion resistance, ensuring that ammunition remains reliable and functional over time. This resistance is particularly important in maintaining the structural integrity of the projectile during storage and use in various environmental conditions.

-

Heat Conductivity: Heat conductivity is another beneficial property of copper. During the firing process, the heat generated is efficiently conducted away from the bullet, preventing overheating and potential damage to the firearm.

Conclusion:

In conclusion, the choice of materials in projectile manufacturing is a critical factor in determining the performance and effectiveness of ammunition. Quality copper, with its unique combination of density, malleability, corrosion resistance, and heat conductivity, emerges as a top choice for creating reliable and high-performance projectiles. As firearms technology continues to advance, the importance of using quality materials in ammunition production, especially copper, becomes increasingly evident in ensuring the safety and effectiveness of firearms users worldwide.